The Ultimate Guide to Laser Metal Engraving: Precision and Artistry in Every Detail

Laser metal engraving has revolutionized the way we create intricate designs on metallic surfaces. This cutting-edge technology combines precision, speed, and versatility, making it a favorite among artists, manufacturers, and hobbyists alike. If you’re curious about how this process works or want to learn more about its applications, read on to discover everything you need to know about laser metal engraving.

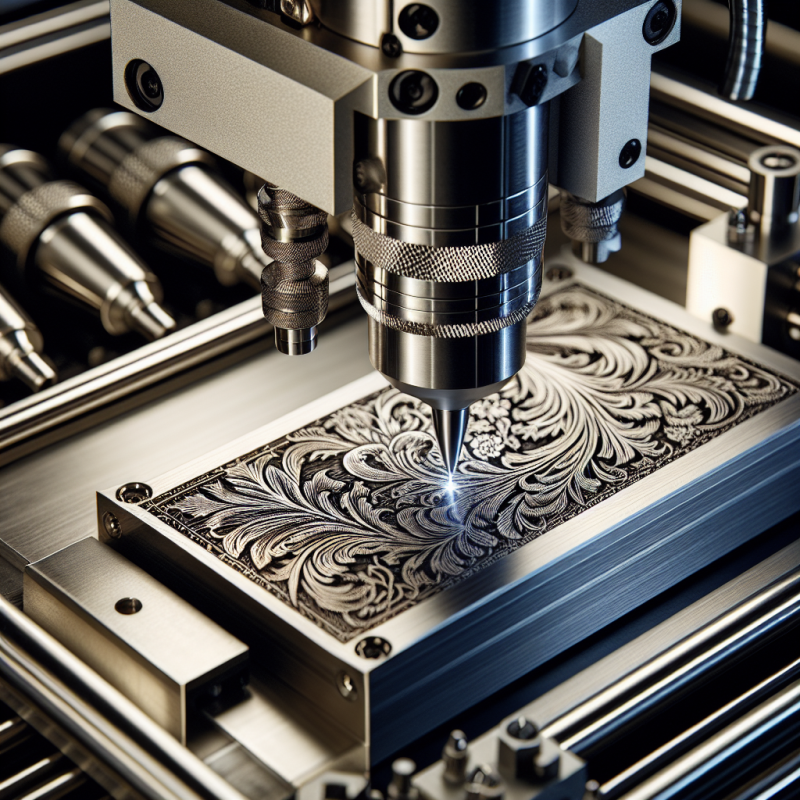

What is Laser Metal Engraving?

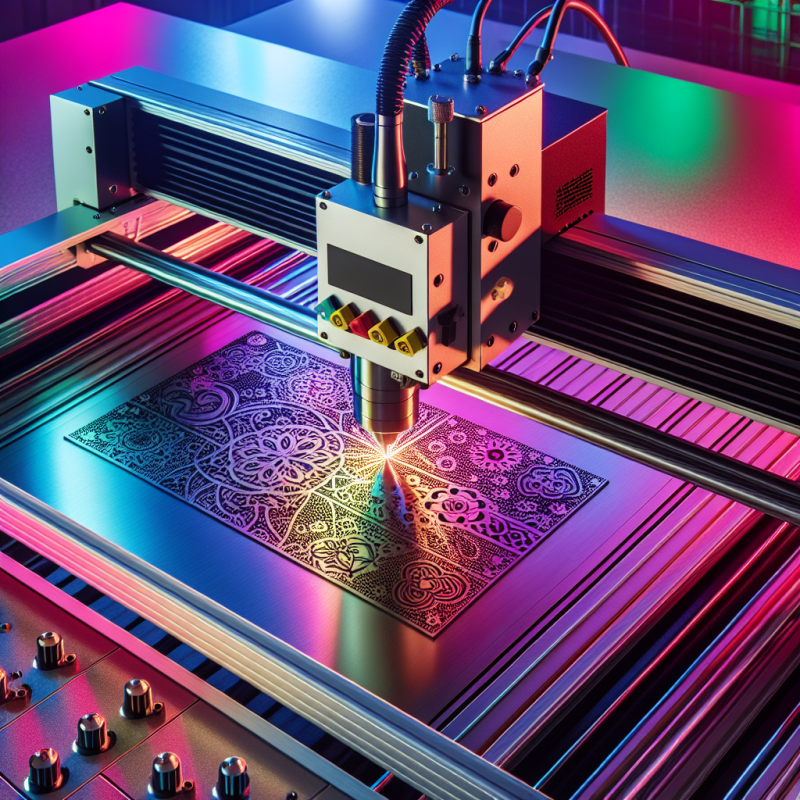

Laser metal engraving is a process that uses a focused beam of light to etch or designs onto metal surfaces. Unlike traditional engraving methods, which rely on mechanical cutting tools, laser engraving utilizes heat to remove material or change the surface properties of the metal. This method offers unparalleled precision and allows for highly detailed patterns, making it ideal for both industrial and artistic applications.

The process begins with a CAD (Computer-Aided Design) file that outlines the desired design. The laser machine then reads this file and uses its high-powered beam to etch the pattern onto the metal surface. The result is a clean, precise, and durable finish that can withstand wear and tear over time.

Advantages of Laser Metal Engraving

There are numerous reasons why laser metal engraving has become so popular in recent years:

- Precision: The laser beam can create designs with extreme accuracy, down to the thousandth of an inch. This level of precision is unmatched by traditional engraving methods.

- Versatility: Laser engraving can be used on a wide range of materials, including steel, aluminum, brass, and titanium. It’s also suitable for both small and large-scale projects.

- Speed: Compared to manual engraving, laser metal engraving is much faster, especially for complex designs or high-volume orders.

- Durability: The engravings created by lasers are permanent and resistant to fading or wear, ensuring long-lasting results.

- Cost-Effective: Once the initial setup is complete, laser engraving can be more cost-effective than traditional methods, particularly for large-scale production.

Applications of Laser Metal Engraving

Laser metal engraving has a wide range of applications across various industries. Some common uses include:

- Jewelry Design: Custom engravings on rings, bracelets, necklaces, and other accessories.

- Award and Recognition Products: Engraving names, titles, or logos on plaques, trophies, and certificates.

- Furniture Manufacturing: Adding decorative patterns or personalized messages to metal furniture components.

- Electronics: Etching serial numbers, barcodes, or branding information onto circuit boards and other electronic components.

- Automotive Industry: Engraving parts identification numbers, logos, or custom designs on car accessories and components.

If you’re interested in learning more about the possibilities of laser metal engraving, consider exploring professional services or investing in your own equipment. For instance, the offers a wide range of solutions for both small and large-scale projects.

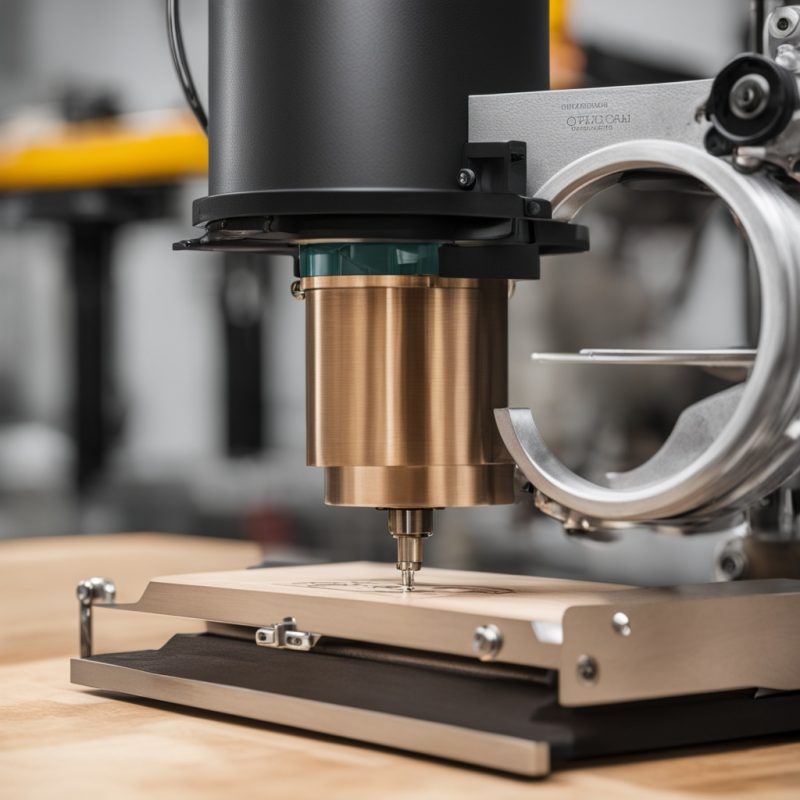

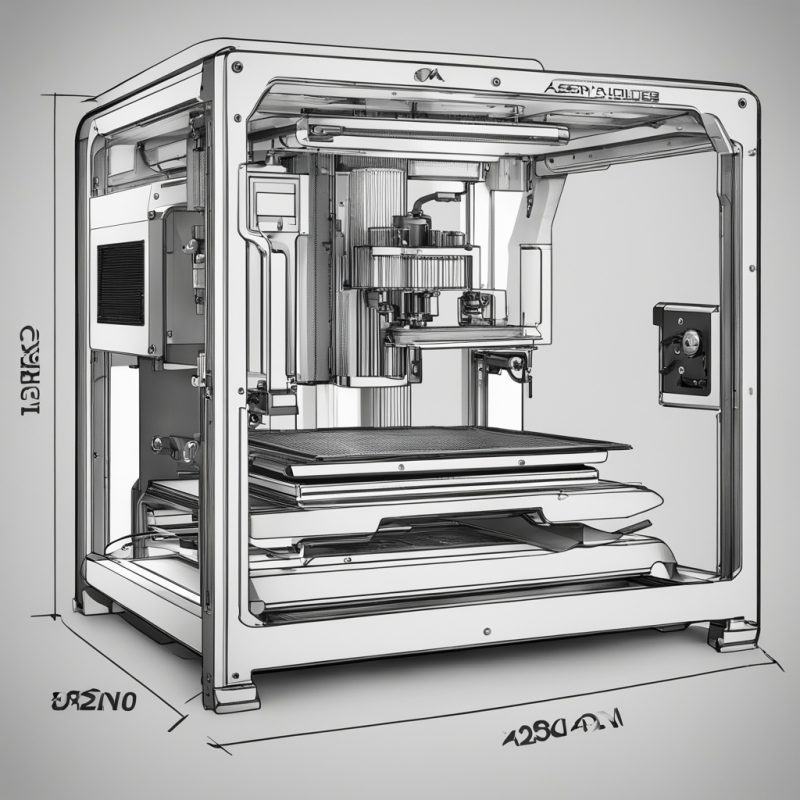

Choosing the Right Equipment for Laser Metal Engraving

If you’re considering laser metal engraving for your project, it’s essential to select the right equipment. Here are some key factors to keep in mind:

- Laser Power: The power of the laser determines how deep and detailed the engraving can be. Higher power lasers are suitable for thicker or harder metals.

- Focus Lens Quality: A high-quality focus lens ensures that the laser beam remains concentrated, resulting in sharper engravings.

- Machine Build Quality: Look for machines with robust construction and reliable components to ensure longevity and performance.

- Software Compatibility: Ensure that the laser machine is compatible with your CAD software and can handle complex designs.

If you’re unsure where to start, consider consulting with experts or reviewing customer reviews before making a purchase. For example, the offers detailed product descriptions and resources to help you make an informed decision.

Best Practices for Laser Metal Engraving

To achieve optimal results with laser metal engraving, follow these tips:

- Prep Your Material Properly: Clean the metal surface thoroughly before engraving to ensure the best possible finish.

- Test First: Always test your design on a scrap piece of metal before engraving the final product. This will allow you to fine-tune settings and avoid costly mistakes.

- Use Proper Safety Gear: Laser engraving produces heat, sparks, and fumes. Wear protective eyewear, gloves, and a mask to stay safe.

- Optimize Settings: Adjust the laser power, speed, and focus based on the type of metal and thickness to achieve the desired depth and finish.

Common Questions About Laser Metal Engraving

If you’re new to laser metal engraving, you might have some questions. Here are answers to some frequently asked questions:

1. How deep can a laser engrave into metal?

The depth of the engraving depends on the power of the laser and the type of metal being engraved. Most lasers can create engravings ranging from 0.001 inches to several millimeters deep.

2. Can I engrave on any type of metal?

Yes, but different metals have varying levels of reflectivity and conductivity. Some metals, like aluminum and brass, are easier to engrave than others. Always test your material first.

3. Is laser metal engraving permanent?

Yes, laser engravings are highly durable and resistant to wear, making them ideal for long-lasting markings.

Conclusion

Laser metal engraving is a versatile and precise method that has transformed the way we create designs on metal surfaces. Whether you’re a professional artist or a hobbyist, understanding this technology can open up new possibilities for your projects. By choosing the right equipment, following best practices, and experimenting with different techniques, you can achieve stunning results with laser metal engraving.

If you’re ready to take the plunge into the world of laser metal engraving, consider exploring resources like for high-quality equipment and expert advice. With a little practice and patience, you’ll be creating beautiful engravings in no time!