“

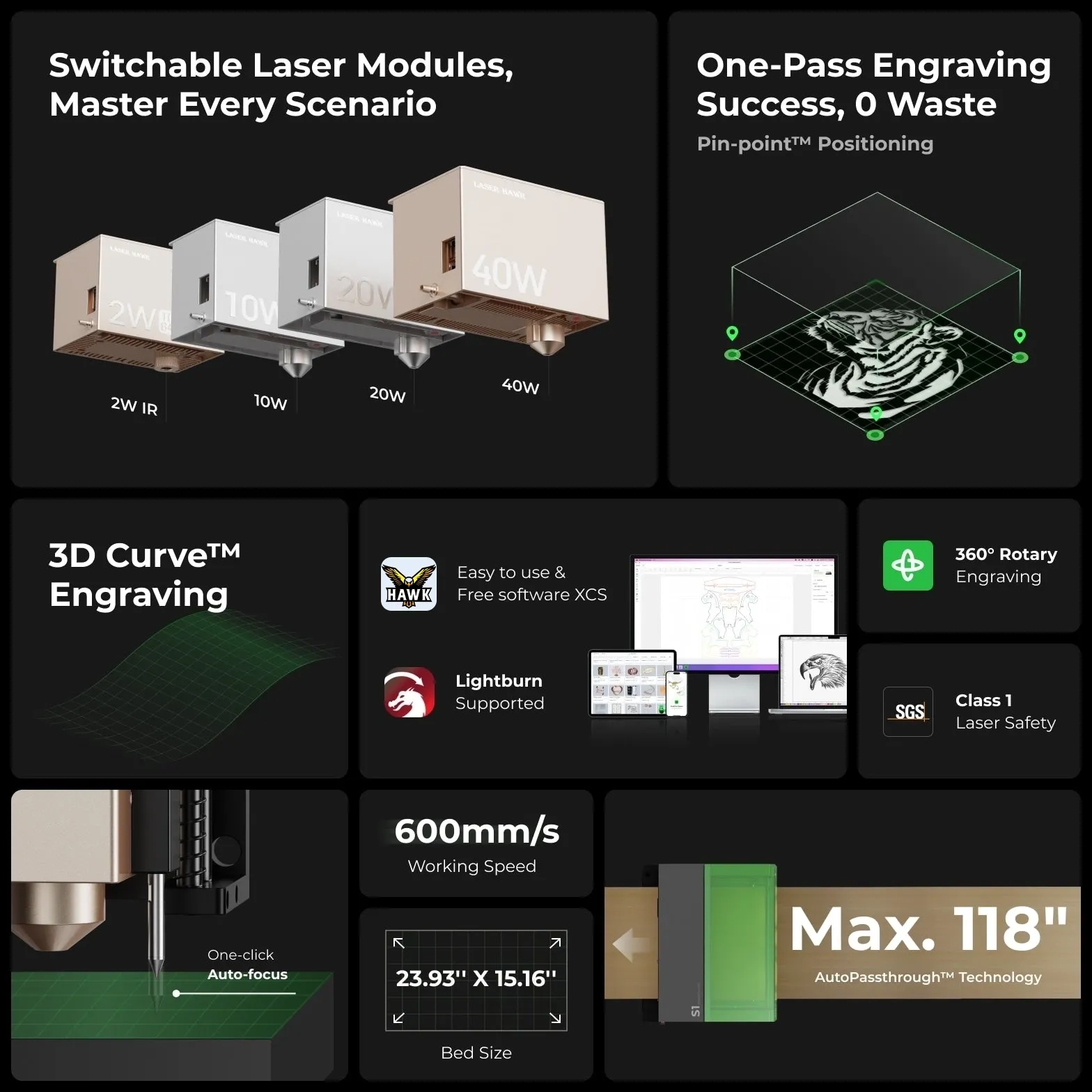

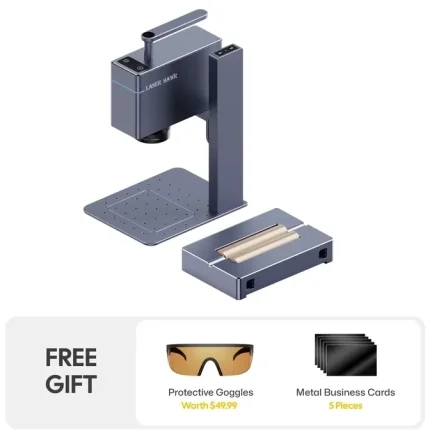

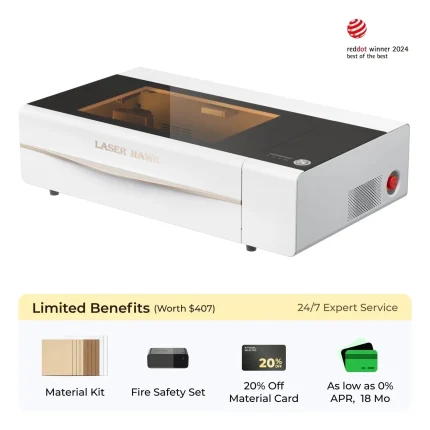

Introducing the Hawk S1 Enclosed Diode Laser Cutter, a cutting-edge solution for precision laser cutting and engraving. Designed to meet the demands of both hobbyists and professionals, this versatile machine is perfect for a wide range of applications, from intricate jewelry designs to robust metal engraving.

Key Features:

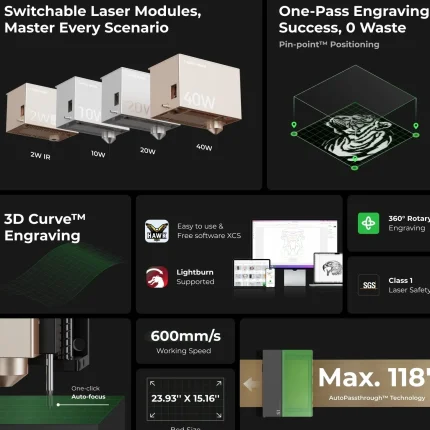

- High Precision Engraving: The Hawk S1 delivers exceptional detail, making it an ideal choice for jewelry laser engraver projects. Whether you’re working with delicate metals or intricate patterns, this machine ensures flawless results every time.

- Enclosed Design: Safety and convenience are at the forefront with the enclosed design, providing a secure environment for laser operations while keeping the workspace clean and organized.

- Rotary Laser Engraver Compatibility: Equipped with advanced rotary capabilities, the Hawk S1 can handle cylindrical objects with ease, making it a perfect fit for rotary laser engraver tasks such as customizing bottles, glasses, and more.

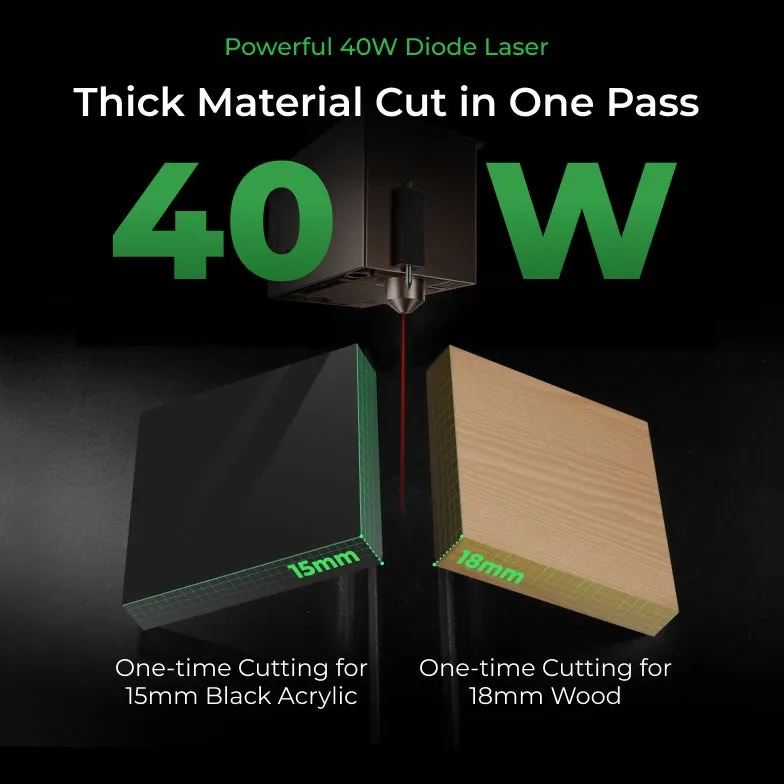

- Metal Engraving Excellence: Unlike many diode lasers, the Hawk S1 excels in laser engraver for metal applications. Its powerful diode laser can etch and mark on a variety of metal surfaces, offering unparalleled versatility.

- User-Friendly Interface: With intuitive controls and easy-to-use software, the Hawk S1 is accessible to users of all skill levels, ensuring a seamless experience from setup to completion.

Why Choose the Hawk S1?

- Versatility: From Ortur laser engraver enthusiasts to professional jewelers, the Hawk S1 adapts to your needs, offering a wide range of applications in one compact machine.

- Durability: Built with high-quality materials, the Hawk S1 is designed to withstand rigorous use, ensuring long-lasting performance and reliability.

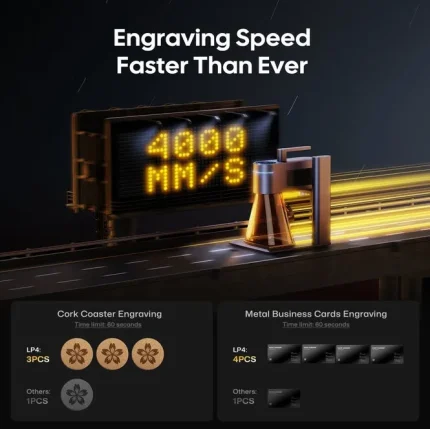

- Innovative Technology: Incorporating the latest advancements in laser technology, the Hawk S1 delivers superior results, setting a new standard for diode laser cutters and engravers.

Transform your creative vision into reality with the Hawk S1 Enclosed Diode Laser Cutter. Whether you’re crafting intricate jewelry, personalizing metal items, or exploring new artistic possibilities, this machine is your ultimate tool for precision and innovation.

More you like:

Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE | Laser for engraving machine✔ Laser engraver for wood✔ Hawk P2S CO2 cutter laser | Wood laser cutter✓Best laser engravers for home✓Laser engrave LaserHawk LX1 Series | Best laser engraver ✓ Laser cutter engraver✓Laser engraving machines✓LaserHawk LH1 Pro | Xtool laser engraver ✔Laser engraver machine ✔Hawk F1 IR+DIODE | Best laser engraver ✓ Laser cutter engraver✓Laser engraving machines✓LaserHawk LH1 Pro | Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter | Best laser engraver ✓ Laser cutter engraver✓Laser engraving machines✓LaserHawk LH1 Pro | Laser engraving machine✓Laser cutter and engraver✓Laser engravers✓Diode Laser Engraver✓Laserhawk LH5 | Laser cutter and engraver ✔Laser engraver for metal ✔Hawk S1 Enclosed Diode Laser Cutter

Wei Tanaka –

★★★★★ Exceptional laser engraving quality with pinpoint accuracy. The machine is intuitive, and the software is user-friendly. Fast engraving speeds boost productivity. Sturdy build, highly reliable.

Ji-hoon Cho (verified owner) –

**Experience with Laser Engraver as a Small Business Owner**

As a small business owner specializing in custom leather goods and personalized metal engravings, I have had a transformative experience with our laser engraver. Here’s a concise overview of my journey:

1. **Specific Project Experience**:

– **Materials Used**: The laser engraver has been instrumental in creating intricate designs on various materials, including thick leather for wallets, acrylic for name tags, and stainless steel for personalized items.

– **Material Behavior**: Each material presented unique characteristics. Leather required precise power settings to achieve deep engravings without burn-through, while acrylic needed careful speed adjustments to maintain clarity. Stainless steel demanded specific software settings to prevent discoloration.

– **Challenges & Solutions**: Initial challenges included burn marks on dark leather due to improper focal length and overlapping lines in complex patterns. These were resolved by meticulously adjusting the focal length and switching to vector mode for certain designs, ensuring cleaner results.

2. **Business/Creative Impact**:

– **Workflow Improvement**: The laser engraver significantly sped up production, especially with batch processing of similar items once settings were optimized.

– **Customer Feedback**: Customers appreciated the precision and personal touch, leading to positive reviews and repeat business. A standout example was a custom leather journal featuring an intricate family crest that turned out flawlessly.

– **ROI & Opportunities**: The investment paid off quickly through increased sales and the ability to offer higher-end products, boosting average order value.

3. **Comparison & Value**:

– **Previous Tools**: Before the laser engraver, manual methods were time-consuming and less precise. The laser tool saved hours weekly, enabling more creative designs.

– **Cost-Effectiveness & Time Savings**: The machine’s efficiency justified its cost, allowing me to take on more custom orders with intricate details that were previously unattainable.

This experience highlights the laser engraver’s role in enhancing my business operations and customer satisfaction, making it an invaluable tool for my creative endeavors.

Ming Sato –

“Exceptional laser engraver! Impressive precision & detail in every cut. User-friendly software & intuitive controls boost workflow. Swift engraving speeds coupled with robust build quality make it a reliable, 5-star tool.”